Microgate and Vicor partner to unlock deep space secrets

Learn how high density power modules help colossal Earth-based telescopes enhance deep space images

Semiconductor manufacturers are placing greater demands on Automatic Test Equipment (ATE) companies to design test systems that will meet the ever-increasing IC demand as quickly and reliably – and with as little added cost as possible.

IC manufacturers consider Cost of Test (CoT) as a cost adder that, while required and necessary, only subtracts from product margins, requires ever increasing factory floorspace and does not improve cycle time and yield.

ATE system manufacturers need to develop test systems that meet the technical needs of new IC products and don’t contribute to yield loss and take up the same or less factory floorspace as the generation being replaced.

High-density and high-efficiency Vicor power modules enable ATE system design engineers to implement new power delivery networks that will allow for increasing test head pin count in the same or smaller size test head. New data center, military, automotive and industrial ICs consume ever-increasing amounts of power and have many, varied voltage levels.

The Vicor modular approach to power enables ATE manufacturers to readily scale power levels and support different voltages to enable rapid development and fast time-to-market.

Industry-leading power density up to 8kW/in3

Up to 98% efficiency

Scalable PDN implementation

Sine amplitude converter topology minimizes EMI

Microgate and Vicor partner to unlock deep space secrets

Learn how high density power modules help colossal Earth-based telescopes enhance deep space images

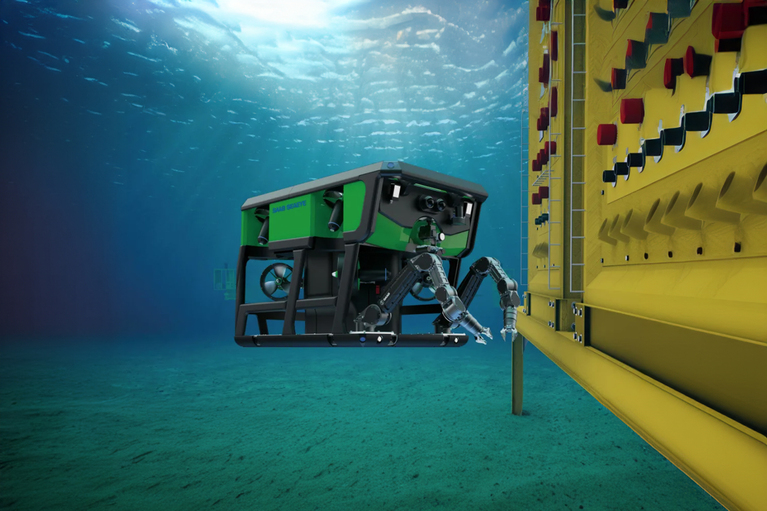

Power modules enable world's most advanced all-electric work-class ROV (eWROV)

Saab UK introduces versatile, environmentally-friendly eWROV that achieves world class performance using compact, thermally-adept power modules

Powering Innovation eBook: Volume 1 – Saving the environment

Technological breakthroughs to protect and preserve the environment

Powering Innovation eBook: Volume 2 – Protecting and saving lives

Innovative solutions that protect and deliver lifesaving materials and services