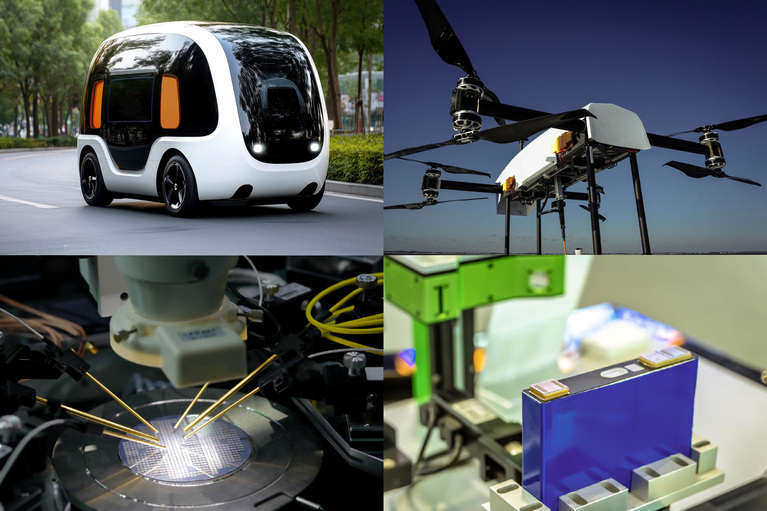

Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

Automated test equipment (ATE), instrumentation, and battery formation and test (BFT) systems OEMs are finding it more difficult to reduce the “cost of test” while trying to keep up with increasing innovation. In addition, manufacturers of high-performance components struggle keeping pace with increased demand and yield expectations set by their end customers.

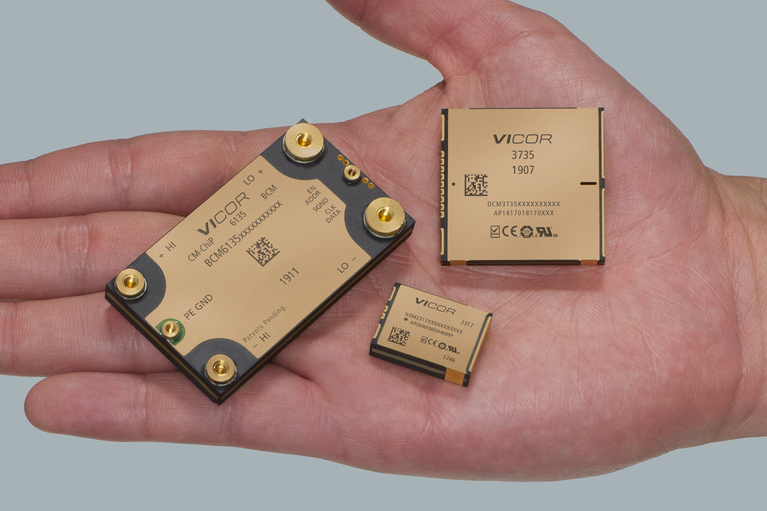

With industry leading power density, the three compact modules shown are capable of handling up to 6kW of power which is significantly higher than the closest competitive solution. Our breakthrough power dense module solutions give ATE and BFT manufacturers the flexibility and scalability to design and manufacture systems that format and test a greater number of devices in parallel without having to expand its current footprint while at the same time offering instrumentation OEMs solutions that deliver low noise and best-in-class thermal management.

Using miniaturized power modules with up to 5x the density, the modular approach uses less real estate, leaving more room for functionality. High efficiency modules require much simpler thermal management and allow for flexible and scalable designs that are simpler and quicker to design and update.

Unlike complex discrete solutions and inflexible “silver box” power systems, power delivery networks using power modules is quick and easy to design and implement. Accommodating new loads — or changes in power needs in a design — is easily accomplished by replacing or adding modules.

Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

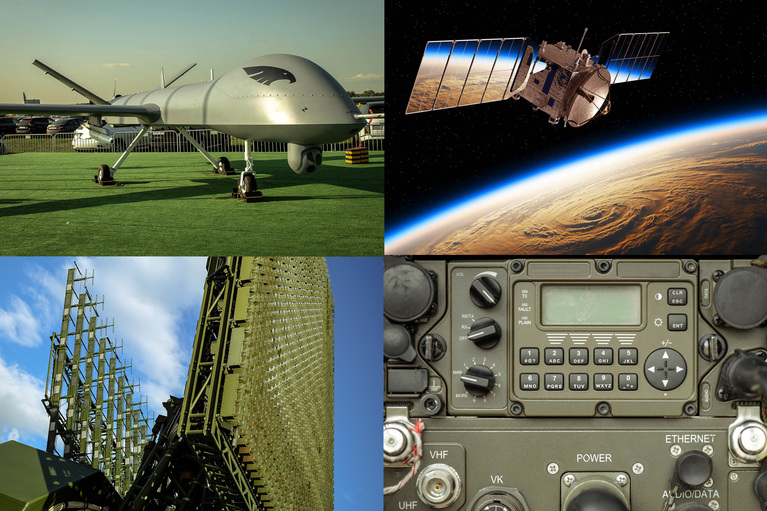

Innovative reliable power solutions for mission critical applications

A collection of technical resources aimed at educating users on the benefits of using modular power in aerospace, defense and space applications

Test and instrumentation glossary of terms

A comprehensive list of commonly used test and instrumentation terminology

The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

The future of standardized defense platforms using MOSA, SOSA and VPX open architectures