高密度功率模組簡化和縮小電動汽車電源系統設計

Vicor 電源模組為電動汽車應用注入創新。瞭解三款汽車級新產品將如何徹底改變未來的電源設計

When electronic equipment is connected to the AC mains, it has the potential to generate common-mode electrical noise. If this is allowed to flow back on to the mains supply line, it can disturb other equipment also connected to the same line.

Manufacturers design capacitor-based power line filtering into their systems to decouple any such common-mode noise produced by the equipment’s power supply, preventing it from reaching other equipment through the mains power line. The reliability of these capacitors is critical to the safety of the equipment’s users.

Line filter capacitors are classified either as X-capacitors or Y-capacitors. X-capacitors are connected between line and neutral, to protect against differential mode interference. Their failure does not create conditions for dangerous electric shock, although it can create a fire risk. However, Y-capacitors are designed to filter out common-mode noise, and are connected between line and chassis; if they short-circuit, they create a risk of shock to the user.

Y-capacitors are designed to enhanced electrical and mechanical reliability standards. Capacitance values are also limited to reduce the current passing through the capacitor when AC voltage is applied, and reduce the energy stored to a safe limit when DC voltage is applied. Capacitors must be tested to applicable standards to qualify them for use as Y-capacitors.

The EN 132400 Standard was issued on 26 June, 1995 replacing all the European National Standards in force up to that date. This was identical to the International Standard IEC 60384-14 2nd Edition 1993. Since then, to make CENELEC and IEC standards identical in name as well as specification, the European Standard EN 132400 has been superseded by EN 60384-14 that is identical to the International Standard IEC 60384-14. Any European national body can issue approvals, with validity recognized by the bodies of all the other CENELEC member countries with no need to repeat the tests.

USA: UL 1414 for across the line applications and UL 1283 for Electromagnetic Interference filters Canada: CAN/CSA C22.2N°1 and CAN/CSA 384-14 China: GB/T14472

EN 60384-14 defines sub-classifications for both types. X1 capacitors are used for high pulse applications, while X2 and X3 types are used for general-purpose applications with different peak pulse operating voltages and peak value surge voltages. Y-capacitors, which are used to bridge operational insulation, are classified as Y1, Y2, Y3 or Y4 according to type of bridged insulation as well as AC and peak voltage ratings. Y1 class capacitors are rated up to 500VAC, with a peak test voltage of 8kV. Y2 capacitors have 150 to 300VAC ratings and a peak test voltage of 5kV. Y3 capacitors are rated to 250VAC with no peak test voltage specified. Y4 capacitors are rated to 150VAC with a peak test voltage of 2.5kV.

These include impulse voltage, endurance and active flammability tests. Application and parameters for these tests depend on the capacitor classification and sub-classification.

Two common types are metallised paper/film and ceramic. For Y-capacitors, ceramic types are less expensive than metallised film, but unstable over time and temperature and less mechanically stable. Ceramic failure mode also tends toward short circuit, whereas metallised paper and film types tend towards open circuit.

Vicor products including FARM, ARM and AC Front End have filters that include Y-capacitors. Refer to the FARM Design Guide and Application Manual for an example of an integral input filter comprising a common-mode choke, Y-capacitors and X-capacitors.

高密度功率模組簡化和縮小電動汽車電源系統設計

Vicor 電源模組為電動汽車應用注入創新。瞭解三款汽車級新產品將如何徹底改變未來的電源設計

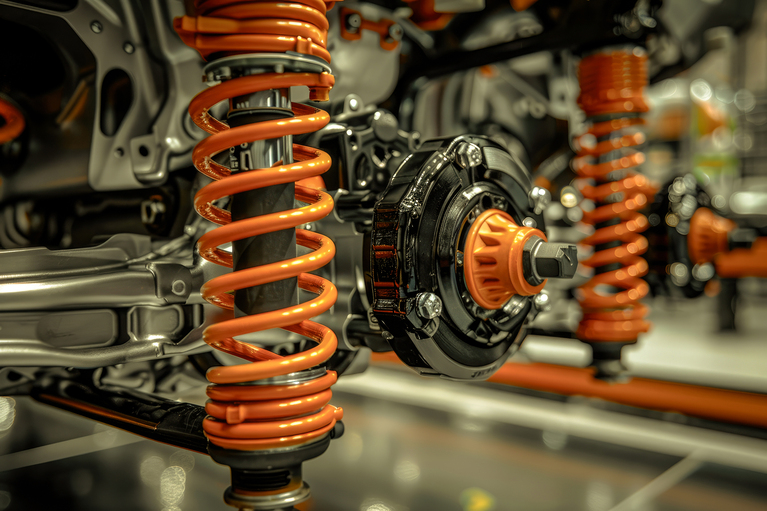

高密度電源模組推動主動懸架技術日趨成熟

主動懸掛系統已從 20 世紀 90 年代的測試版發展成為今天的 48V 驅動系統。瞭解電源模組對電源系統設計的影響

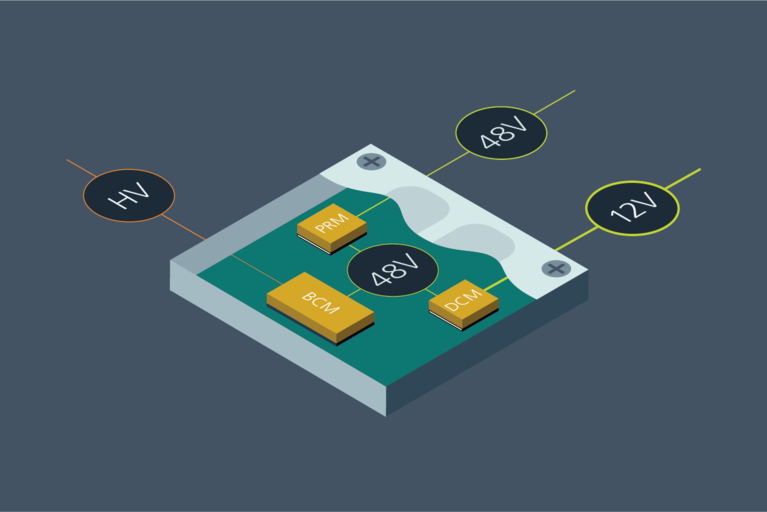

基於 MHz 開關頻率的器件助力實現 DC-DC 轉換器和 EMI 濾波器的小型化

想像一下,使用 DC-DC 轉換器解決方案來利用高頻開關的優勢,而不會發生傳統解決方案的缺點

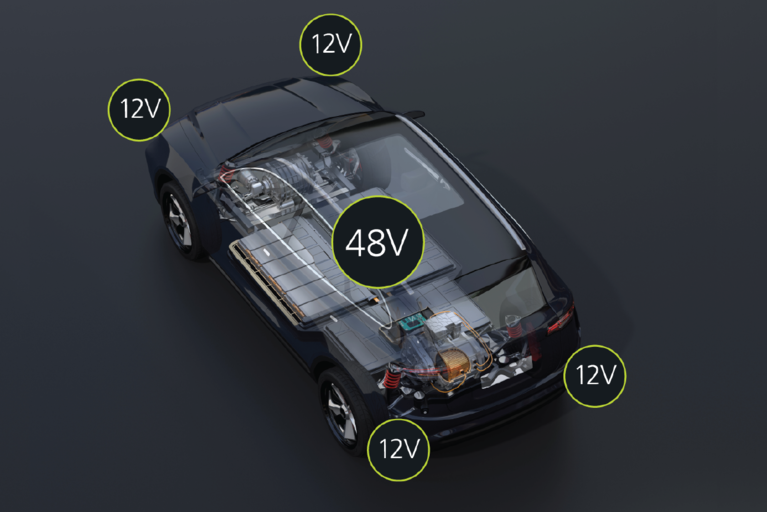

採用 48V 區域架構,打造面向未來的先進電動汽車

隨著原始設備製造商(OEM)採用 48V 電源架構,他們正努力優化其電源系統設計。 Vicor 的高功率密度模組可為 48V 區域架構提供峰值效率