用于新太空的供电网络

太空环境十分严酷,要求完美的可靠性。Vicor 耐辐射电源模块能承受新太空的严酷考验

太空是一个充满挑战且不容许任何差错的环境,要求设备具备最高性能和绝对可靠性。因此,仔细选择最适合应用的产品至关重要。对于低地球轨道(LEO)和中地球轨道(MEO)卫星而言,耐辐射部件是确保卓越性能和延长任务寿命的最佳选择。Vicor 公司成熟的耐辐射高密度电源模块性能卓越,并经过严格测试,能够承受太空环境的严苛考验。

作者:Ken Coffman,高级现场应用工程师;Salah Ben Doua,首席应用工程师

太空中的电子系统面临诸多危险,包括持续受到电磁波和粒子辐射的影响。半导体器件特别容易受到粒子辐射的影响,这可能导致系统故障甚至永久性损坏。

然而,并非所有太空应用都需要相同程度的辐射防护。例如,深空探测任务使用昂贵的耐辐射强化组件;而当今的新太空应用,如运行在 LEO(低地球轨道)和 MEO(中地球轨道)的卫星,则只需要“耐辐射”的组件和电路。

如图 1 所示,电磁波辐射和粒子辐射虽然相关,但对系统的影响却有所不同。单个粒子的质量虽小,但可以加速到极高的速度。它们还可能携带电荷——通常由于原子轨道中的负电荷电子被剥离而带正电荷。

图 1:辐射谱。

Particle radiation can cause physical damage, particularly to semiconductor crystal lattices and E that damage can prove to be either permanent and/or cumulative. Systems also experience temporary upsets when electrons are dragged into depletion regions and make a non-conducting region conduct.

Alternatively, if positive ions replace doping atoms in a crystal matrix, permanent damage can result, making a semiconductor conduct when it shouldn't causing permanent damage as a result of circuit malfunction.

Much of the radiation damage is cumulative, so mission length will always be an inescapable factor.

In today’s fast-paced new space business environment, costs to launch and to replace dead satellites are substantial, so careful design is important.

Select components for radiation tolerance. Some semiconductor process nodes have improved radiation performance. Bipolar semiconductors can be selected for displacement damage ratings, while wide-bandgap (GaN) FETs have inherent radiation tolerance. Some epoxies and aluminum electrolytic capacitors outgas in a vacuum, making them inappropriate for use in space environments.

Product lots should be sample tested for radiation performance to account for lot-to-lot variations.

Multiple instances of systems can be implemented. Physical redundancy is a safeguard. If one fails, another can take over. In some systems, there are three systems operating in parallel so that if one disagrees with the other two, its output can then be ignored.

Power MOSFETs can be de-rated so that after inevitable VGS threshold degradation, the device is still functional at the end of the mission life.

Shielding can protect sensitive electronics, but if the particle energy is high enough, cascading shield particles can add to the problem.

Circuitry can be added to monitor performance, disconnect and restart inconsistent systems if a fault is recoverable.

But, regardless of design strategies and power supply topologies, New Space electronic systems must be rigorously analyzed, simulated and tested for environmental and radiation performance.

Soft-switching topologies (versus hard-switched power converters) can make a system less sensitive to parasitic effects like ringing that increases voltage stress on switching components.

Factors for evaluating a topology include power density, efficiency, transient response, output ripple, electromagnetic interference (EMI) emissions and cost.

Switching loss occurs during MOSFETs via gate-charge requirements and drain-to-source capacitance.

Switching losses increase with, and thus limit, switching frequency. Body-diode conduction losses detract further from power-conversion efficiency in hard-switched converters.

Though GaN FETs do not have a physical body diode, they do have a reverse conduction mode clamping at several volts and this can make the GaN dead-time conduction period very challenging to manage.

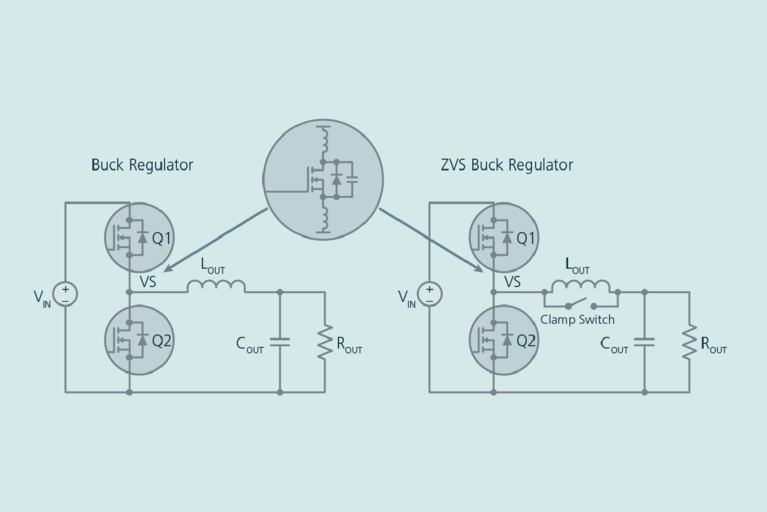

In a synchronous, hard-switched buck topology, the high-side FET turns on when it has the maximum voltage across it and conducts its maximum current during the turn-on portion of the operating cycle (see Figure 2, left side). The greater the input voltage, the higher the power loss, so converters in high voltage-ratio applications (e.g., 28V to 3.3V) deliver poorer efficiency than the converters with greater conversion ratios (e.g., 5V to 2.5V).

Figure 2: Topology parasitics. Conventional, hard-switched buck converter (left) versus zero-voltage switched (ZVS) buck converter (right).

Soft switching reduces switching losses. One example of soft switching is the zero-voltage switching (ZVS) technique, which improves conversion efficiency across a range of power topologies. ZVS switches the high-side FET on when the voltage across the switch is at or near zero (see Figure 2, right side).

Operation of a clamp switch with the ZVS technique allows the converter to store a small amount of energy in the output inductor when both high-side and low-side switches are off. The converter uses this otherwise-wasted energy to discharge the high-side FET’s output capacitance and charge the synchronous FET’s output parasitic.

Taking the FET’s output capacitance out of the switch’s turn-on behavior will help to desensitize FET selection regarding Cgd and, consequently will allow designers to focus on on-state channel resistance instead of traditional figures of merit such as the product of channel resistance and gate capacitance.

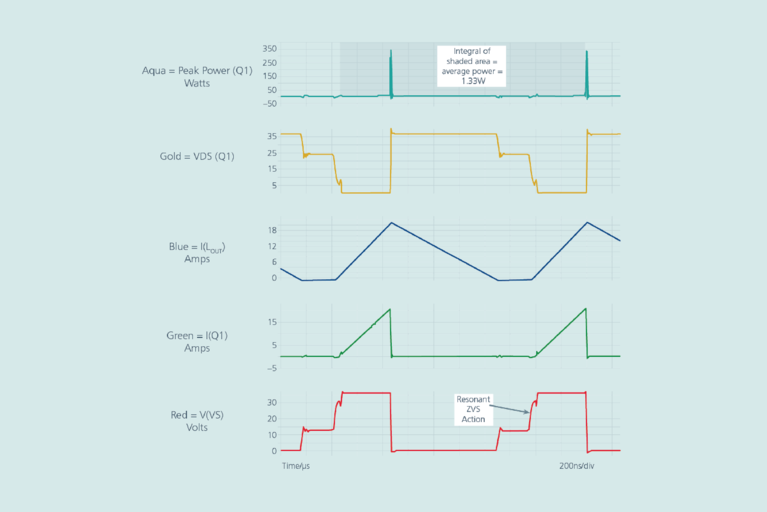

This method of driving the high-side FET during turn-on avoids exciting the switch’s parasitic inductance and capacitance, which tend to resonate, inducing large voltage spikes and ringing in hard-switched topologies (see Figure 3a). By eliminating spikes and reducing ringing (see Figure 3b), ZVS removes a power-loss term and eliminates a source of EMI emission.

Figure 3: Hard-switching versus soft-switching wave forms.

Eliminating the voltage spikes from the switching behavior also allows designers to select lower-voltage FETs with lower RDSON to improve efficiency.

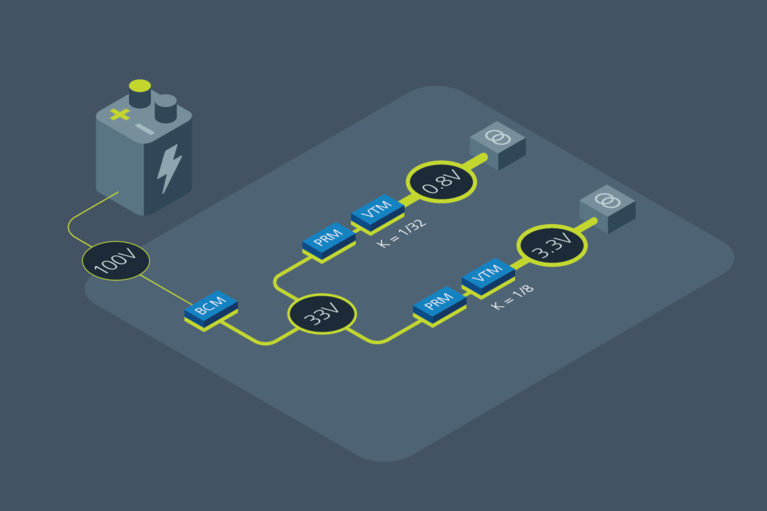

Vicor is among a number of companies to have developed and employ soft-switching techniques in its radiation-tolerant power module solutions for powering high-performance communication ASICs (see Figure 4) dedicated to MEO and LEO satellite applications. The system modules use ZVS buck-boost topology for the PRM™ and ZVS and ZCS Sine Amplitude Converters™ (SAC™) for both the BCM® and the VTM™.

Figure 4: High-power resonant (ZVS and ZCS) topology modules.

The small size of the VTM allows placement as close as possible to the ASIC. Optimizing the power distribution network (PDN) is critical when dealing with high currents consumed by modern ASICs, FPGAs, CPUs and GPUs.

Consequently, Vicor modules combine soft-switching solutions, rad-tolerant active components and automotive-qualified passive components.

To mitigate the single event function interrupt, all radiation-tolerant modules include completely redundant powertrains operating in parallel. If one powertrain gets upset due to a single event, its protection circuits force a power-off-reset. During the reset interval, the redundant powertrain carries the full load and after the reset both powertrains operate in parallel again.

Among many other factors, selecting a topology and switching mode are important factors when it comes to designing new space power converters.

This article was originally published by New Electronics.

Ken Coffman, Senior Field Applications Engineer, is assigned to Vicor’s New Space Initiative. He is located in Phoenix, Arizona. You can email Ken at kcoffman@vicr.com.

Ken Coffman, Senior Field Applications Engineer

Salah Ben Doua, Principle Applications Engineer, has 30 years of experience in the field of power design and has been supporting Vicor customers for over 20 years, providing expertise and advice in the development of dc-dc and ac-dc power systems in a multitude of areas, including aerospace and defense, industrial, rail, lighting and communications. Salah received a Ph.D. from the National Polytechnic Institute of Toulouse, specializing in power conversion.

Salah Ben Doua, Principal Applications Engineer