By Patrick Kowalyk, Automotive Principal Field Applications Engineer

As the automotive industry transitions to electric vehicles (EVs), design engineers

face challenges developing the underlying electrical architectures. For example, large capacitive loads in 800V traction motor inverters require dedicated pre-charge circuitry to avoid damaging inrush currents.

At the same time, EV designers continually strive to reduce system size, weight and cost. The challenge lies in designing robust and reliable electrical architectures that incur minimal design and cost overhead. Achieving this balance requires engineers to consider new approaches to power system design.

With a dense power module, engineers can design novel architectures that balance the tradeoffs associated with vehicle pre-charging. A fixed-ratio converter module is the key to creating the most efficient pre-charge system.

Taming high inrush currents

An electric vehicle's operation requires four main components: a traction battery, DC-DC converters, a traction motor inverter and an electric motor. Within this structure, the battery provides high-voltage (800V) DC power to the traction motor inverter, which in turn provides AC power to drive the motor.

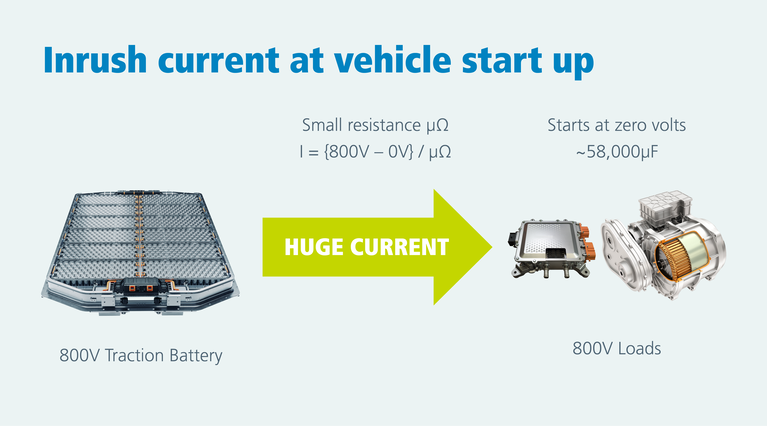

The delivery of power from the traction battery to the traction motor inverter presents safety and reliability challenges. The traction motor inverter sporadically draws high current, so integrating large DC-link capacitors to maintain stable DC power is a requirement. In many vehicles, the total DC-link capacitance can be approximately 58,000μF, representing a huge capacitive load.

At vehicle start up, where this capacitance is uncharged (0V), connecting the traction battery directly to the traction motor inverter results in high inrush currents. Where the battery wiring has a resistance on the order of micro-ohms and the battery operates at 800V, the resulting current in amps is defined by Ohm’s Law: I = (800C – 0V)/R.

This high inrush current presents safety risks to the system, including ground faults, equipment damage and blown fuses (Figure 1). Additionally, the high dV/dt associated with charging the DC-link capacitance can result in ringing and damage to components.

Figure 1: At vehicle start up, the charging of a traction inverter’s DC-link capacitance can result in huge inrush currents that are potentially damaging to the equipment.

The best practices of proper pre-charging

To address these issues, electric vehicles employ a pre-charging circuit, a preliminary mode that limits the inrush current during the vehicle’s power-up procedure.

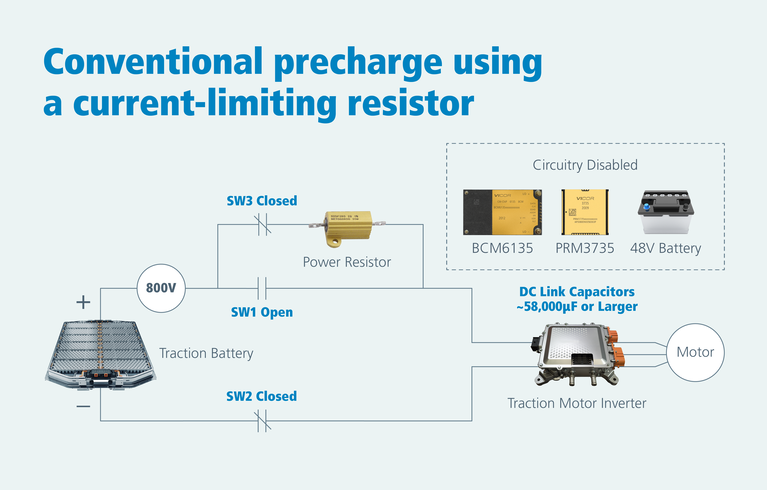

In most EVs, pre-charging employs dedicated contactors and a current-limiting resistor between the traction battery and the traction motor inverter (Figure 2). During pre-charge, SW1 is open, while SW2 and SW3 are closed. In this mode, the vehicle pre-charges the DC-link capacitance through the series resistor R1, effectively limiting the inrush current. When the DC-link capacitors have reached 800V, pre-charge is complete, SW3 opens and SW1 closes, allowing the vehicle to operate in normal conditions.

While this method of pre-charging works, it is far from ideal. A primary shortcoming is that it requires the use of extra components, including a pre-charge contactor that is robust but large, heavy and expensive. These extra components are not desirable in EVs, where space, weight and cost are at a premium.

Another challenge is that pre-charging from the high-voltage bus is prone to heat-related failures. For example, repeated cycling caused by turning the vehicle on and off multiple times in a short period exposes the pre-charge resistor to high currents for extended durations. This repeated power draw causes the resistor to overheat, exposing the system to shorts and faults that can destroy high-voltage circuits. Protecting pre-charge circuitry requires dedicated safety circuits, which further increase system bill-of-materials (BOM), weight and cost.

Figure 2: During pre-charge, a dedicated contactor SW3 connects a series resistor between the battery and inverter. At completion, SW3 opens and SW1 closes, reconnecting the battery to the inverter.

Thinking outside the box using fixed-ratio converters

The Vicor BCM® family of fixed-ratio converters offers a unique form of voltage conversion that unlocks a new and improved way to perform pre-charging.

Fixed-ratio converters are unregulated, isolated DC-DC converters that achieve peak efficiency of 98%. They operate similarly to AC transformers by providing fixed-ratio voltage bucking or boosting, which is defined by the converter’s turns-ratio or K factor (Figure 3). Most importantly, these devices are bidirectional, meaning that the same module can step the voltage up or down depending on the direction of the current flow.

Figure 3: Fixed-ratio converters step DC voltage up or down by a pre-determined ratio depending on the direction of current flow, delivering high efficiency in the process.

In the context of EV pre-charging, the value of fixed-ratio converters is that they uniquely enable pre-charging from the low-voltage bus.

All EVs use two batteries: the main traction battery, which operates at 400V or 800V, and the low-voltage battery, which operates at 12V or 48V. The low-voltage battery powers low-voltage auxiliary equipment, such as the radio and system controls, when the vehicle is off. When the vehicle is on, the auxiliary low-voltage equipment is then powered by the traction battery through a dedicated DC-DC converter and regulator (Figure 4). This conversion is present in all EVs and is generally achieved through unidirectional solutions like switched-mode power converters.

Figure 4: The use of a fixed-ratio converter and a voltage regulator simultaneously enables pre-charging from the low-voltage battery during pre-charge and powering the low-voltage bus from the traction battery during normal operation.

Designing a pre-charge approach using high-density power modules

With the introduction of the fixed-ratio power converter module, power system designers can achieve a means of pre-charging that requires no additional components and incurs no additional cost or weight.

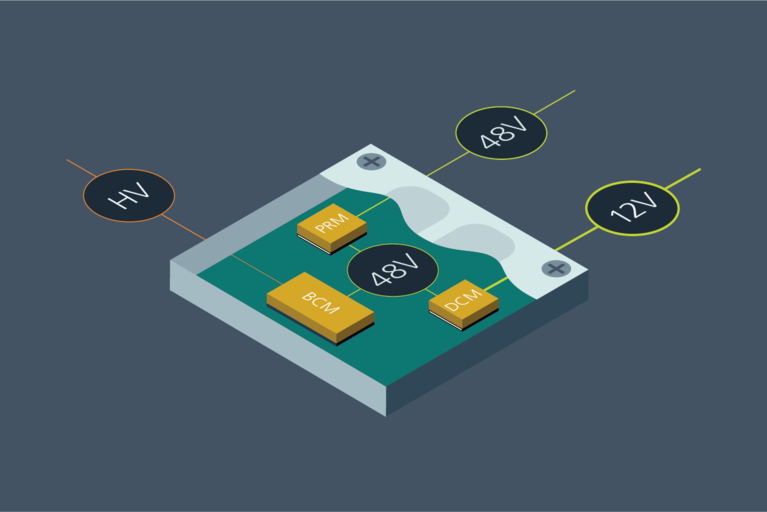

Instead of pre-charging the traction motor inverter’s DC-link capacitance directly from the traction battery, designers can use fixed-ratio converters to perform pre-charging from the low-voltage battery. With this design, the standard DC-DC converter used to power the low-voltage bus from the high-voltage bus is replaced with a fixed-ratio converter, such as the Vicor BCM6135, and a DC-DC regulator, such as the Vicor PRM3735. Importantly, the total component count is unchanged from the original implementation.

During pre-charge, SW1 and SW2 are open, completely disconnecting the traction battery. In this mode, the 48V from the low-voltage battery is regulated via the PRM3735 and then stepped up by the BCM6135 to the 800V needed to pre-charge the traction motor’s DC-link capacitance. Since the PRM3735's output current is controllable, this architecture achieves pre-charging without high and uncontrolled inrush currents.

Once pre-charging is complete, SW1 and SW2 are then closed. Leveraging the bidirectional nature of fixed-ratio converters, the same fixed-ratio converter and DC-DC regulator can now swap polarities and step the 800V from the traction battery down to 48V to power the low-voltage bus.

The benefits of this approach are significant and manifold:

- Pre-charging without more cost or components

This architecture allows power system designers to achieve reliable and controlled pre-charging without having to add parts. Using the same components that already exist in legacy systems (the DC-DC converter and DC-DC regulator), designers can both pre-charge and power the low-voltage bus from the high-voltage bus. Compared to conventional pre-charging schemes, which require additional contactors, resistors and safety circuitry, this method significantly reduces BOM. The lower component count directly translates to decreased system size, weight and cost.

- Highly reliable, less risky

A fixed-ratio converter is more reliable than conventional pre-charging through a series resistor and is not prone to overheating or failure.

- Most power-efficient approach

The fixed-ratio converter method is highly efficient. Given that the DC-DC regulation occurs without any voltage conversion (48V-to-48V regulation), the entirety of the voltage conversion occurs in the fixed-ratio converter. With efficiencies as high as 98%, the fixed-ratio converter is nearly lossless, ensuring minimal power is wasted in the process. These savings result in greater vehicle range and decreased need for thermal management.

Power modules reduce BOM, cost and weight

While the transition from ICE vehicles to EVs marches on, there is a growing need for more affordable, smaller and lighter power systems. This can only be achieved through innovative approaches to designing better EV power delivery networks.

With high-efficiency fixed-ratio converters, Vicor is unlocking new architectural options by providing unprecedented design flexibility for power system designers. Pre-charging approaches that employ existing components mark just one application showcasing the capability of fixed-ratio power converter modules. As power systems evolve further and become more integral to the automotive space, fixed-ratio converters will help enable a more sustainable and affordable future.

Patrick Kowalyk has been providing automotive power systems for over 6 years, but has been practicing engineer for decades. Patrick’s deep technical knowledge has been instrumental in growing the Vicor automotive business. His technical mastery of electrical engineering as related to power modules, topologies and architectures is second to none. Kowalyk has been a catalyst for helping design compact, efficient power systems for OEMs and Tier One customers. He holds a BS in Electrical Engineering from the Illinois Institute of Technology.

Patrick Kowalyk, Automotive Principal Field Applications Engineer