High-density power modules simplify and downsize EV power system design

Vicor power modules infuse innovation into EV applications. Learn how three new automotive-grade products will revolutionize the future of power designs

Distribution of power is obviously a critical element of any electronic system. Simply getting the power to the load, however, is only a part of the story: in addition to optimizing efficiency, other constraints include reducing EMI, ensuring the system is rugged or developing a power chain that takes less space, allowing more room for other parts of the system.

There are several different ways that engineers can reduce the space required by power distribution, and most applications will use a combination of the seven techniques below:

One simple approach is to select components that are optimized for high power density, as using smaller components obviously reduces the space required. Increasing power density means that the waste heat has to be removed from a smaller volume, requiring greater thermal efficiency from new innovative packages. Examples of such innovations are the double-sided cooling capabilities of our Converter housed in Package (ChiP) technology and the Vicor Integrated Adapter (VIA) Packaging.

Heat sinks are large, heavy items that can increase the space required dramatically. If they require forced-air cooling, then the size of the power system increases even more, and the reliability falls. So eliminating heat sinks is an important way of reducing space.

Of course engineers must still remove the heat generated, so they either need to choose a component that reduces waste heat by increasing efficiency, or find a part that is more thermally efficient.

A few packages, notably the chassis-mount VIA package, can use the equipment housing as a heat sink, allowing the elimination of separate heat sinks, even in higher power applications

Even in space-constrained applications, there are often unused places. For example rack-mount systems typically don’t make use of the space in the side of the cabinet or behind the door. Placing parts of the power system in places that would not otherwise be used reduces the effective space required.

Many industrial applications use DIN rails for power distribution, and a good example of this approach would be placing components behind the rails. This is difficult to achieve using conventional power supplies, which tend to be too large to fit behind the rails, but new thinner power components are emerging. Parts based on VIA packaging technology are only about 9mm thick, and can therefore fit in this otherwise unused space, leaving more room for the rest of the system.

Output capacitors often need to be large to ensure that the power system can respond to transient load demands. Factorized Power Architecture (FPA), however, allows the capacitance to be moved to the input of the VTM, which is typically several times the voltage that is seen at the output. As energy is proportional to the square of the voltage, by moving the capacitance designers replace the large bulk capacitance with a small ceramic capacitor.

The classic hard-switched PWM converter generates a significant amount of EMI, which must be eliminated by filtering, often taking a significant amount of space. Moving to a high-frequency soft-switching topology, means that the filtering is less demanding, reducing the space that is required.

Vicor’s ZVS/ZCS topology is the technology leader, as it not only eliminates the EMI caused by hard switching, but it also operates at higher frequencies, which can further reduce the size of the filters required. Its inherent high efficiency also means that power components using the topology dissipate less heat, reducing the heatsinking requirements.

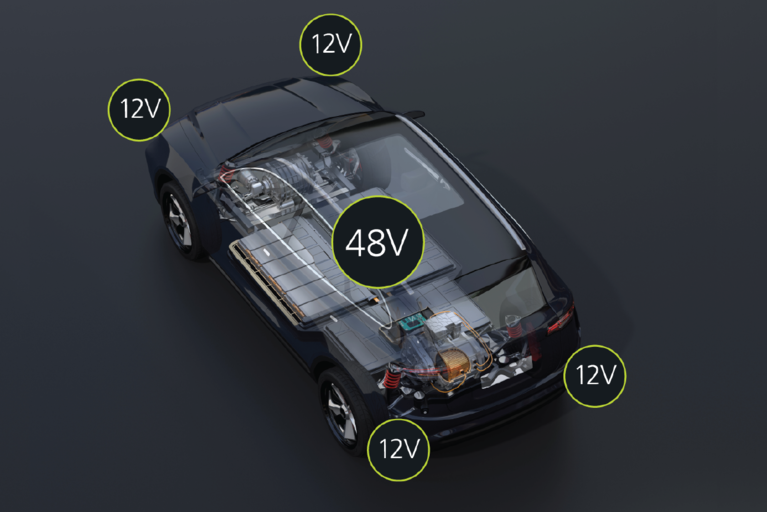

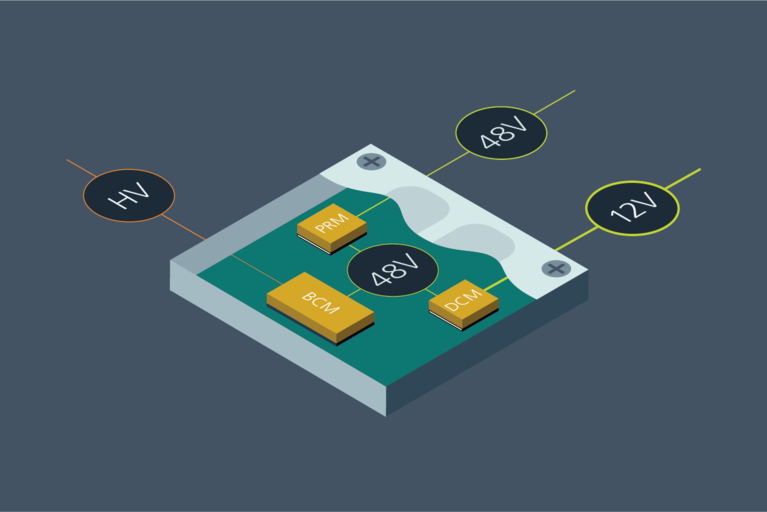

Although any system will have fixed requirements for the load voltage, power system designers can change the bus voltages used. By switching to a High Voltage DC (HVDC) distribution, or by moving intermediate bus voltage from 12V to 48V, the size of conductors can be reduced, and the overall system made smaller and more efficient.

When voltages need to be stepped down by a large ratio – e.g. converting a 48V bus to a 1.5V rail for a microprocessor – power system designers have traditionally needed to use two-stage conversion to optimize efficiency. Now new components, such as our 48V buck family, are available that not only reduce size by performing the conversion in a single stage, but also increase efficiency over a two-stage approach.

High-density power modules simplify and downsize EV power system design

Vicor power modules infuse innovation into EV applications. Learn how three new automotive-grade products will revolutionize the future of power designs

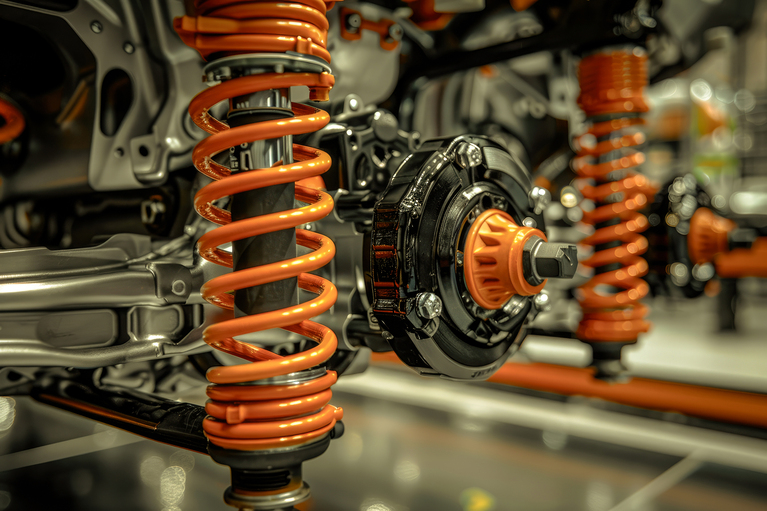

Active suspension comes of age bolstered by high-density power modules

Active suspension has evolved from 1990s beta model to today’s 48V-driven system. See the impact power modules have made on power system design

MHz switching frequency-based devices enable miniaturization of the DC-DC converter and EMI filters

Imagine using DC-DC converters solutions to harness the benefits of high-frequency switching without incurring conventional shortcomings

Future-proof advanced EVs by adopting 48V zonal architectures

As OEMs move to 48V, they consider how to optimize their power system design. Vicor power-dense modules deliver peak efficiency for 48V Zonal Architectures