Power delivery networks for New Space

Space is an unforgiving environment demanding flawless reliability. Vicor radiation-tolerant power modules are proven to withstand the rigors of New Space

Vicor's Rob Russell, VP of satellite programs, shares his institutional insights into the trends and key influencers shaping the future of satellites and the rapid commercialization of space.

By Rob Russell, VP of Satellite Business Unit

Figure 1: To meet worldwide internet demand, bandwidth will need to increase by at least 20x. To achieve this over 100,000 new satellites will need to be deployed in the next ten years and high density power solutions will be integral to driving LEO and MEO satellite market.

Q: What are the market drivers for LEO and MEO constellation satellite OEMs and service providers?

A: The main driver for low-Earth-orbit (LEO) and medium-Earth-orbit (MEO) communication constellation satellites is the soaring demand for internet bandwidth. This expected bandwidth growth is driven by several macro trends, such as the shift to cloud-based computing, IoT connectivity, AI growth, and the constantly increasing appetite for streaming services. Adding satellite bandwidth will have a multiplier effect on the overall bandwidth requirements by being able to reach markets that are currently underserved by terrestrial providers. These LEO and MEO constellations will provide the communications backbone needed to achieve complete global connectivity.

Q: What are the general challenges the developers of these satellites face?

A: Deploying hundreds or even thousands of satellites in lower orbits creates some significant challenges for system architects and developers. The cost for a satellite, including the launch cost, has to come down by at least an order of magnitude compared to geostationary (GEO) and deep-space satellites to make this solution economically viable. At the same time, the throughput capability of each satellite needs to be maximized to meet the increasing bandwidth requirements. Optimizing the throughput per satellite is even more important when taking into consideration the fact that the FCC and other governmental agencies restrict the numbers of satellites that can be launched.

Moreover, the typical expected life for a LEO satellite is three to seven years, so the development cycle times need to be reduced by a factor of 2x or 3x from historic rates, to keep up with replacements. This makes faster time-to-market from suppliers even more important for OEMs in today’s burgeoning satellite market.

Q: What are the power challenges they face?

A: The dueling requirements of shrinking the size and cost of the satellites while improving the throughput drives satellite developers to implement the most advanced communications technology they can find. One of the key elements of this effort is the use of advanced communications processors. These processors, in turn, require advanced power solutions capable of very low (sub-1V) voltages and currents that can exceed 130A. These solutions must also be very power dense, minimizing both the board space and weight, all while maintaining an appropriate degree of radiation tolerance for the mission.

Legacy space power solutions are typically capable of providing a small fraction of the current needed for these applications in a much larger footprint, forcing satellite developers to look at innovative ways to solve the problem. In addition to the technical challenge, one of these large constellations can require tens of thousands of power converters, which is orders of magnitude higher than the legacy space infrastructure has historically been able to support.

Q: What unique capabilities does Vicor utilize to meet these challenges? What power architectures and semiconductor platforms do you use and why?

A: Vicor uses its proven Factorized Power Architecture (FPA™) in radiation-tolerant products. FPA provides a reliable architecture for providing low-voltage/high-current solutions for processor power. Vicor FPA solutions have been evolving for over 15 years, and are deployed in high-performance computing applications, aerospace and defense applications, and more recently, in artificial intelligence applications.

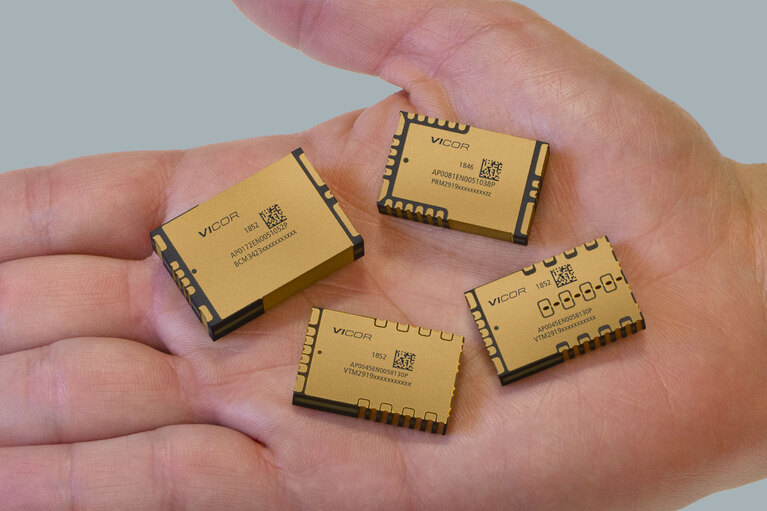

To achieve and maintain our global technical leadership position, we have long designed our own control chips to get the most out of our unique topologies and packaging. For other semiconductor components, we work with the top suppliers in the industry and use whatever allows us to get the best performance out of our modules. We maintain the same methodology for our radiation tolerant products, and this allows us to achieve at least a 3x to 5x density improvement over the competition (Figure 1).

Q: How do you ensure low-noise voltage conversion for sound power integrity?

A: One of the key attributes of our FPA components is that they generate very little noise and require much less filtering compared to other solutions. FPA separates the regulation function from the voltage-transformation function, allowing us to put our extremely low-noise VTM module as close to the load as possible where the signal integrity is critical. (Radiation tolerant FPA solutions)

Q: How do you qualify the level of radiation tolerance in Vicor parts?

A: Radiation tolerance is a loose term applied to the idea that NewSpace satellites should be built with adequate radiation tolerance for LEO and MEO altitudes, vs. “radiation hardened” devices typically used for GEO and deeper space missions. The requirements seem to be application-specific and somewhat negotiable. Vicor products were designed and tested to 50krad total ionizing dose (TID), with a single event effect (SEE) rating of 35 MeV-cm2/mg. Furthermore, our parts are immune to single event functional interrupts (SEFI). We achieve SEFI immunity by using redundant powertrains and proprietary control circuitry in each module.

Q: What other environmental conditions do you use for testing the ruggedness and reliability of these products?

A: We do the same MIL-STD-810 tests that we do for our robust MIL-COTS converters for things like shock and vibration and temperature cycling. It is probably a bit overkill for space applications, but it is an integral part of our standard qualification process to ensure we have the most robust design possible.

Q: What future enhancements do you anticipate being added to these products in the next couple of years?

A: We are already working on enhancing our current generation of products with respect to both efficiency and radiation tolerance. Our FPA modules are inherently flexible, and it is relatively easy to develop variants of our parts for different bus and load voltages. In addition to the current solution, which converts a standard 100V satellite bus to 0.8V/150A and 3.3V/50A processor voltages, I expect that we will develop a similar 28V-processor load solution, as well as solutions that take the satellite bus and creates an isolated, regulated 28V, 15V or 12V bus to power other types of downstream loads.

Figure 2: Vicor rad-tolerant power modules provide a 3 – 5x power-density improvement over the current best-in-class solutions, and a 50% reduction in power losses for 100V bus applications.

This article was originally published by Microwave Journal.

Rob Russell is currently the Vice President of Satellite Business Development and has worked at Vicor Corporation for over 10 years in various strategic marketing, product marketing, and business development roles. He has over 29 years of sales and marketing experience in the electronics industry. He earned both his BSEE and MBA at the University of Massachusetts. Before Vicor, he worked for Power-One as the Vice President of Product Marketing and Director of Global Strategic Sales.

Rob Russell, VP of Satellite Business Unit

Power delivery networks for New Space

Space is an unforgiving environment demanding flawless reliability. Vicor radiation-tolerant power modules are proven to withstand the rigors of New Space

DC-DC converters for NewSpace applications

Smaller satellites harvest less energy using a modular approach to minimize I2R distribution losses, maximize efficiency and improve transient response

For New Space satellites, radiation tolerance means new design hurdle

Vicor power modules are power dense, reliable and scalable. Furthermore, there are multiple benefits of soft switching in radiation-tolerant power systems

60th Annual AOC International Symposium & Convention

The premier EW and Radar technology event of the year