There is an unprecedented R&D push toward electrification of automobiles, which includes optimizing the power delivery network and the local and global charging infrastructure. Because of the complex nature of the problems, it is necessary to explore new approaches and creative solutions. High density power modules offer tremendous flexibility to design, scale and adapt to the today’s fast pace of automotive electrification.

What is the difference between bidirectional charging and smart charging?

GREEN: Bi-directional charging and smart charging go hand-in-hand. Essentially, bi-directional charging involves a car battery providing power to another load; smart charging is the system intelligence that allows the car to understand and manage the load that it is powering.

Looking at smart charging from a charger perspective, a home charger is a device that can provide power whenever it makes sense. For example, if solar panels on a roof are connected to the internet, it is easy to project the next sunny day when power can be converted and is available to use. The smart charger processes this information and waits and charges the vehicle at the best time when power is available.

MUHEDINOVIC: Bosch is building a full infrastructure for smart charging. This communicates with the power plant, to discover the current price of electricity, whether the grid is flooded with energy that can be used now, and the source of the energy. So smart charging monitors the full charging infrastructure - vehicles, solar panels, the grid, communications and the energy provider.

GREEN: This is happening right now – for example, in the UK since mid-2022, every wall charger needs to be compatible as a smart charger and needs connectivity to provide feedback. Most DC chargers from Tesla can already do this.

How is bidirectional or “two-way” charging used?

GREEN: Bi-directional charging is used to send energy from a car battery to another load. This can take the form of Vehicle to Grid (V2G); Vehicle to Home (V2H); Vehicle to Load (V2L); or Vehicle to Vehicle (V2V).

Very few vehicles have this ability to provide power to other loads, such as the Nissan Leaf and the Ford F150, which can provide 3.6kW of AC power.

Bi-directional charging capability needs monitoring, which is the the role of smart charging, to monitor and manage system power flow. Smart charging can enable and optimize V2G, V2H, V2L or V2V using bi-directional power.

What is Vicor doing to ensure that every EV is compatible with DC fast charging stations along the highway to eliminate range anxiety and accelerate the future of EVs?

MUHEDINOVIC: We see the main challenge as compatibility. Today vehicles come in two voltages, 400V or 800V – the higher the voltage, the faster the charging can be executed.

The issue is that most roadside chargers are 400VDC. For fast charging, OEMs need something that will boost 400V to 800V. Some Tier Ones have solutions that are quite bulky and heavy, weighing approximately 15kgs. Heavy solutions take up space and reduce range.

The incompatibility between 800V batteries and 400V chargers can be solved through “battery virtualization.” Here, the charger “sees” a 400V battery on one side of the onboard charger, even while the 800V battery is connected to the other side. Vicor technology can achieve this.

In terms of weight, the Vicor high-density, high-power modules, such as the Sine Amplitude Converter (SAC), which only needs 3.5 liters, can be used to implement battery virtualization without adding size, weight and complexity. The weight advantage supports greater range.

How is Vicor dealing with evolving power delivery requirements as new approaches to power delivery architecture develop?

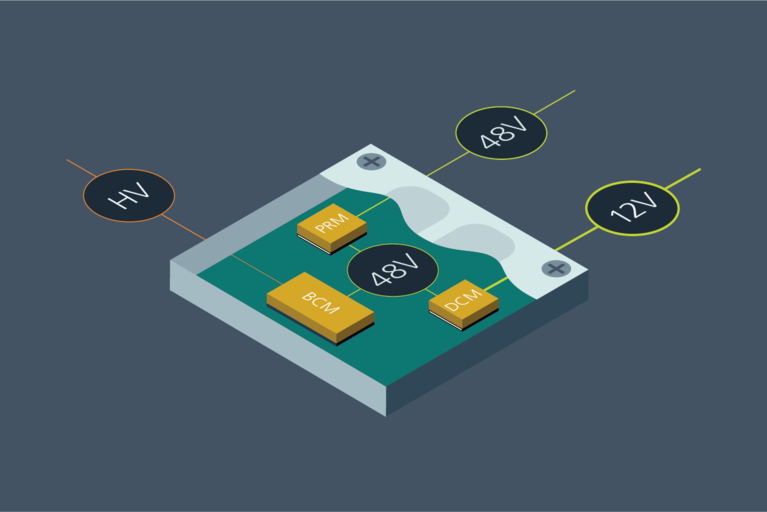

GREEN: Among other things, what Vicor offers is scalability in power and voltage. Compact power modules from Vicor can be placed in parallel to easily increase the power as needed. This means that OEMs only need to characterize and qualify one part, a key advantage that helps the OEM to differentiate their system and get to market faster.

MUHEDINOVIC: Using Vicor power modules, the power delivery network (PDN) can be very different from one vehicle to another, but without needing design expertise or investing a lot of time. Using just a handful of parts OEMs can rapidly configure a PDN uniquely suited their xEV platform. Easy configurability, flexibility and scalability are hallmarks of Vicor power modules. They are the perfect solution for designing today’s fast-paced xEVs.

How important is power redundancy for the future of EVs?

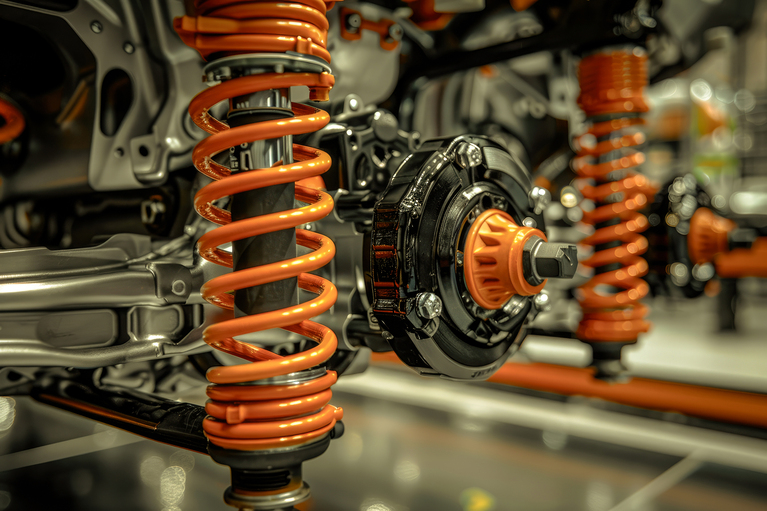

MUHEDINOVIC: With the increased demand for autonomous vehicles, we have also seen a greater demand for more reliable power architectures. So, there is a keen focus on Failure In Time (FIT) rates. For a single component to reach the required FIT rate for ASIL Level D or special function autonomous driving, OEMs are implementing redundancy which helps them reach low FIT rates. To achieve this, they often implement redundant power supplies to ensure there is at least one power supply available to maintain designated loads.

Sometimes manufacturers rely only on the battery and DC-DC converter but in addition they may provide two independent paths to supply the low voltage battery from the high voltage battery, an important factor in the safe redundancy of future EVs. With purely mechanical systems being increasingly replaced by electrical power functions, such as steer by wire and brake by wire, it is essential to ensure that the systems are fully operational even if the HV battery malfunctions or is temporarily unavailable. If the low voltage battery is lost, the DC-DC converter will supply the loads, and if the DC-DC converter is lost, there will be another to maintain the steering and braking for the vehicle.

There are many ways to achieve this. Vicor's advantage is that the architectures provide the needed redundancy in much smaller volumes and weight than the competitors. For example, other solutions need to use up to five liters in volume while Vicor can provide everything in less than two liters, which further simplifies the architecture in a lot less space.

GREEN: Vicor technology, with Sine Amplitude Converter (SAC), can enable battery virtualization and potentially eliminate low voltage batteries from the vehicle while still providing power redundancy. This helps optimize the power delivery network and a high performance and high efficiency power conversion.

This article was originally published by Electronik-DE.